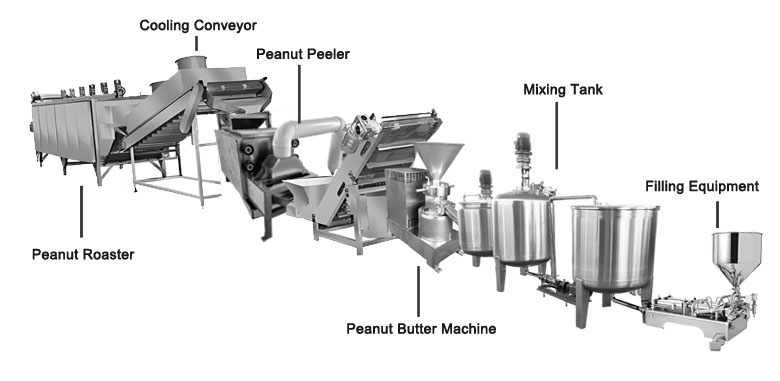

In the field of modern food processing, automatic production line has become an important means to improve production efficiency and ensure product quality. As a part of the food industry, the equipment configuration of peanut butter production line plays a vital role in the smooth production process and the guarantee of product quality. Generally speaking, the equipment configuration of peanut butter production line includes raw material pretreatment equipment, grinding equipment, blending equipment, filling equipment, auxiliary equipment and so on.

Raw material pretreatment equipment.

Raw material pretreatment equipment is used for preliminary treatment of peanuts, including shelling, impurity removal, cleaning and roasting. Common raw material pretreatment equipment includes peanut sheller machine, peanut sieving machine, peanut washing machine, peanut roasting machine, etc. The function is to remove impurities in raw materials, screen clean and hygienic peanut raw materials with the same size, and carry out processing procedures such as roasting, which is convenient for grinding.

Grinding equipment.

Grinding equipment is the core part of peanut butter production line, and its performance directly affects the fineness and taste of the product. According to the production demand, different specifications of grinding equipment such as peanut butter machine can be selected. Peanut butter machine uses high-speed rotation or high pressure to grind the roasted peanuts into a uniform paste, while ensuring the complete retention of nutrients.

Blending equipment.

Blending equipment is the equipment that mixes ground peanut butter with other ingredients. These devices usually include blenders, blending cylinders, etc., and their functions are to fully mix various ingredients to ensure the consistency and stability of product taste.

Filling equipment.

Filling equipment is the equipment that fills the peanut butter into the packaging container. Common filling equipment includes peanut butter filling machine. The selection of filling equipment should consider production efficiency, the shape and size of packaging containers and the degree of automation. Modern filling equipment is usually equipped with automatic control system, which can realize accurate measurement and rapid filling and further improve production efficiency.

In addition to the above parts, the peanut butter production line also needs some auxiliary equipment, such as conveying equipment, packaging equipment. All these auxiliary equipments play the role of connection and support in the whole production line, ensuring the continuity and efficiency of the production line.

In a word, the equipment configuration of peanut butter production line is a systematic project, which needs to comprehensively consider many factors such as raw material properties, production scale and product requirements. Through rational allocation of various equipment, production efficiency can be improved, production cost can be reduced, and product quality and safety can be ensured.