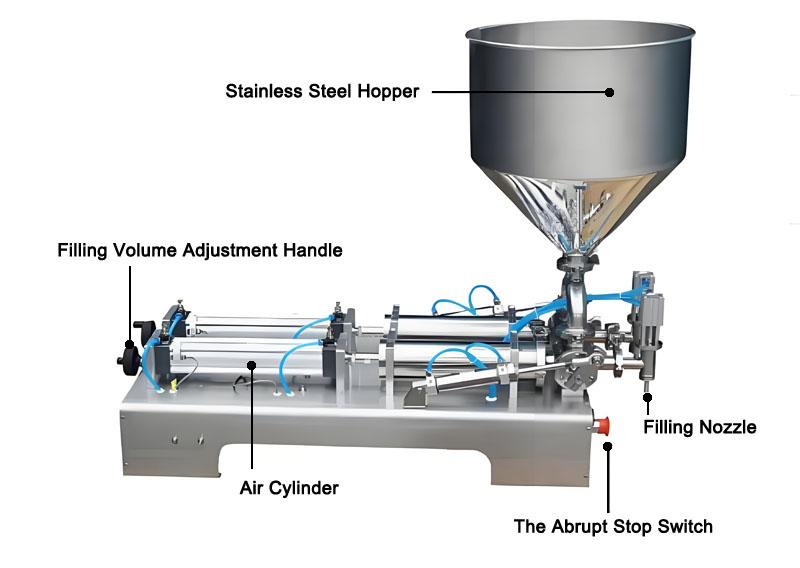

Peanut butter filling machine, as a kind of filling equipment designed for high viscosity products, its excellent performance and wide range of applications make it an indispensable part of the food processing industry.

The following details the core features and advantages of peanut butter filling machine

First, a wide range of applicability

With its unique structural design, the peanut butter filling machine can easily cope with the filling needs of high-viscosity liquid products including peanut butter, sesame paste, salad dressing, seasoning sauce, ketchup and other liquid products. Through the optimized material conveying system, it effectively avoids the jamming phenomenon during the filling process and ensures the continuity and stability of product filling, thus greatly improving the filling quality.

Second, high-precision filling control

The equipment adopts advanced measuring cup filling method, which realizes high-precision control of filling volume through precise metering system and adjustable filling parameters. Whether it is products with different viscosity or different batches of production, the peanut butter filling machine can ensure that the filling volume of each product remains consistent, thus meeting the strict requirements of customers for product quality and stability.

Third, efficient automated production process

Peanut butter filling machine is equipped with full digital display button switch and fully automatic operation mode, which makes the production process extremely easy. Simply place the product on the filling machine and set the corresponding parameters to realize continuous and efficient production. This highly automated production mode not only improves the production efficiency, but also reduces the errors and risks brought by manual operation.

Fourth, flexible container adaptability

In order to meet the needs of different customers, the peanut butter filling machine is designed with replaceable filling head, which can easily adapt to different specifications of containers. At the same time, the equipment also has the function of adjusting the height of the container, making the filling process more flexible and convenient. This design not only improves the utilization rate of the equipment, but also saves customers the cost of buying filling equipment of different specifications.

Fifth, safety and health and easy maintenance

Peanut butter filling machine is made of high-quality materials, featuring durability and corrosion resistance. The contact part is made of stainless steel, which not only ensures the hygiene and safety of the product, but also avoids the risk of chemical reaction with the filling product. In addition, the cleaning and maintenance of the equipment is also very simple, only need to follow the operation manual for regular cleaning and maintenance can ensure the long-term stable operation of the equipment.

In summary, peanut butter filling machine has become the necessary equipment for manufacturers of high-viscosity products by virtue of its wide applicability, high-precision filling control, high-efficiency automated production process, flexible container adaptability, and safe and hygienic easy maintenance. It can not only improve production efficiency, reduce costs and enhance product quality, but also help customers improve production processes and increase profitability. Therefore, for any enterprise engaged in the production of high-viscosity products, investing in a peanut butter filling machine is undoubtedly a wise choice.