Recently, a customer in Malawi purchased our peanut butter production line equipment, including peanut shelling machine, cooling machine, GT-500 peanut butter filling machine and 900 sealing machine, which is designed to improve production efficiency and ensure product quality.

Peanut sheller:

As one of the core equipment of the peanut butter production line, the peanut sheller excels in removing the shells of peanuts. Using advanced technology, the machine delivers high shelling rates and low breakage rates, ensuring that the peanut material is in optimal condition when it enters the subsequent processing stage. Whether you are a large-scale producer or a small-scale processor, the peanut shelling machine is able to satisfy your customers’ needs for high-quality peanuts.

Cooling Machines:

The cooling machine is an indispensable key equipment in the peanut butter production process. The introduced cooling machine has a large cooling capacity of 2 cubic meters, which can quickly reduce the temperature of roasted peanuts. In addition, the equipment can also be used to cool other nuts, such as sunflower seeds, cashews, almonds, etc., with a wide range of applications. All parts that come into contact with the material are made of high quality stainless steel, ensuring that the equipment is durable and easy to clean.

Peanut Butter Filling Machine:

GT-500 Peanut Butter Filling Machine is known for its high accuracy and efficiency. With a touch screen interface, the machine is easy to operate and can be programmed by the user to adapt to the filling needs of different sized containers. Whether it is peanut butter, jelly or other sauce products, GT-500 filling machine can ensure the filling process is precise and error-free, and significantly improve the production efficiency.

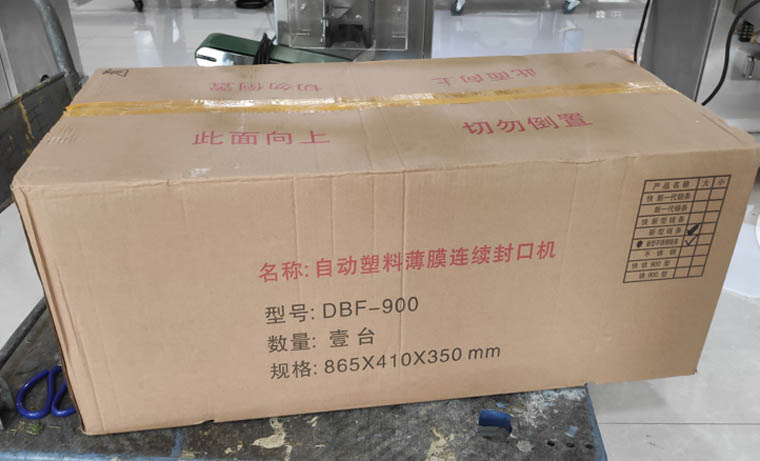

Model 900 Sealing Machine:

The Model DBF-900 Sealer is the last key process in the peanut butter production line. With its reliable sealing performance, this equipment ensures that peanut butter remains fresh and uncontaminated after filling. Whether in the food, pharmaceutical or fine chemical industries, the Model 900 Sealer provides excellent sealing results to meet diverse production needs.

High-quality equipment and after-sales service help Malawi customer achieve production goals

The peanut butter production line equipment introduced this time is made of high quality materials and rigorously tested to ensure high efficiency and durability. Not only do we provide our customers with state-of-the-art equipment, but we are also committed to providing comprehensive after-sales service to ensure that our customers receive timely support during the operation of their equipment.

We are honored that our customers in Malawi have chosen us as their peanut butter production line equipment supplier. In the future, we will continue to dedicate ourselves to providing our customers with the best quality products and services, and we look forward to working with more customers to promote the development of the global food processing industry.