Peanut butter, one of the world’s most popular sauces, is highly prized for its rich flavor and high nutritional value. It is rich in healthy fats, proteins and carbohydrates as well as vitamins and various essential minerals such as calcium, iron, magnesium and zinc. Investing in a fully automated peanut butter production line is crucial for producers looking to expand their peanut butter business. So what exactly are the key pieces of equipment included in an efficient automated peanut butter production line?

Essential equipment in a peanut butter production line

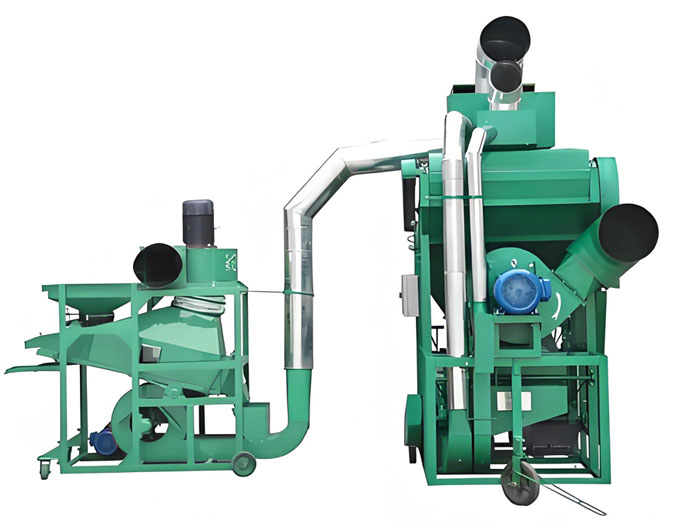

Peanut Sheller

The first step in peanut butter manufacturing is to remove the hard shells of raw peanuts. The peanut sheller can effectively separate the kernel from the shell in preparation for roasting.

Peanut Roaster

After shelling, peanuts need to be roasted to enhance their flavor and aroma. The roasting process also helps to loosen the peanut skins, making peeling easier. Various types of roasters are available, including rotary drum roasters and belt roasters.

Peanut Coolers

After roasting, peanuts need to be cooled quickly to prevent over-roasting and maintain their texture. A peanut cooler ensures even cooling, which is critical before the peeling stage.

Peanut Peeler

Peelers remove the outer skin from peanuts to improve the texture and appearance of the final peanut butter product. Dry peelers are often used in peanut butter production lines to maintain the quality of the peanuts.

Peanut Butter Making Machine

The peanut butter machine is the centerpiece of the production line. It uses a high-speed rotor and a small stator with adjustable clearance. As the peanuts pass through, they are subjected to shearing, friction, high-frequency vibration and eddy currents, resulting in a smooth, creamy peanut butter texture.

Degassing Tank

The degassing tank removes air bubbles from the peanut butter to prevent oxidation and ensure a longer shelf life. This is a critical step before filling and packaging.

Peanut Butter Filling Machine

The final stage of the peanut butter production process is packaging. Automated filling and packaging machines ensure that jars or pouches are accurately filled, sealed and labeled. This step maintains product quality and enhances brand image.

Why choose an automated peanut butter production line?

Improved Efficiency & Consistency: Automated production significantly increases throughput and ensures consistent product texture.

Improved sanitation and reduced contamination: Reduced manual labor reduces the risk of contamination.

Reduced Operating Costs: Automation reduces labor costs, is easy to maintain and provides long-lasting performance.

About KMEC: Your Trusted Peanut Butter Equipment Supplier

KMEC has been specializing in the development and optimization of peanut butter production line equipment for decades, and our mechanized, corrosion-resistant, and user-friendly production lines are highly regarded by customers around the world. Contact KMEC today to customize the best peanut butter production solution for you!