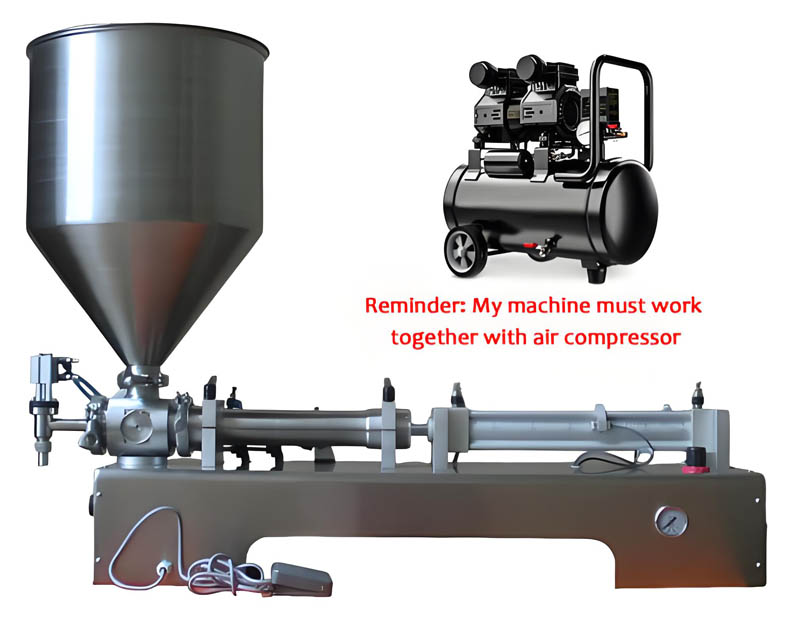

The semi-automatic horizontal peanut butter filling machine is a quantitative filling machine that uses compressed air as power and comprises precision pneumatic components. It is widely used in the food, pharmaceutical, cosmetic, and special industries. Apart from peanut butter, it is also used for filling tahini, sesame butter, sweet sauce, ketchup, jam, cream, and other viscous paste products in the food industry. All liquid filler equipment undergoes regular quality assurance inspections measuring against a matrix of performance factors, as well as various configurations of peripherals such as nozzles and liquids.

The GT series filling machines are available in single-head, double-head and explosion-proof models to flexibly meet different production requirements and provide efficient liquid filling for your production line.

Specification of Peanut Butter Filling Machine

| Type | GT-PF1 |

| Automatic Grade | Semi-automatic |

| Driven Type | Pneumatic |

| Voltage | 220V/50HZ |

| Dimension(L*W*H) | 930*280*720mm |

| Weight | 28.5kg |

| Certification | CE |

| Filling volume | 10-100ml,20-300ml,30-500,ml,100-1000ml,200-2000ml,200-3000ml,300-5000ml |

| Packing speed | 1-25 bottle/min |

Feature of Peanut Butter Filling Machine

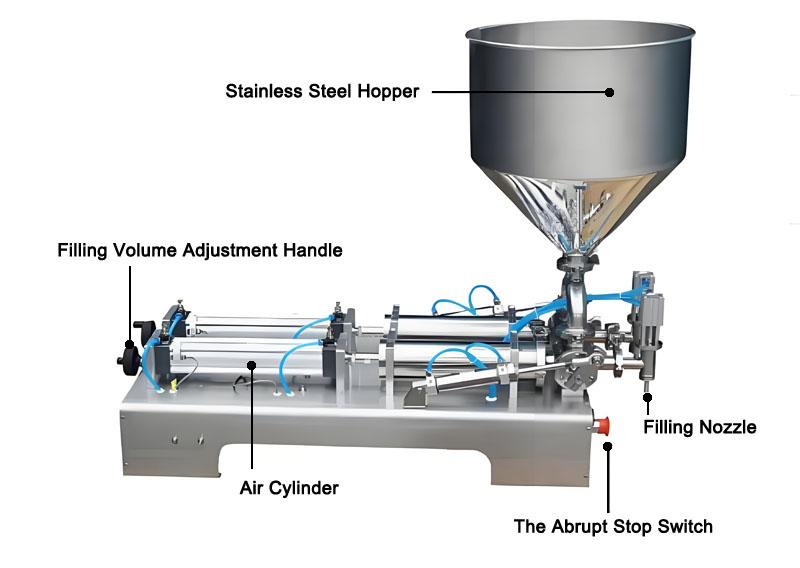

- High quality material: the whole machine is made of stainless steel, which is not only wear-resistant and durable, but also meets the strictest hygiene standards to ensure that the product is not contaminated.

- High-precision metering: The batch filling system is equipped with a high-precision adjusting device, with a metering accuracy of up to 98% (i.e. less than 2% error), ensuring the accuracy of each filling.

- High-quality piston cylinder: The piston cylinder of the filling machine is made of PTFE material, which has excellent sealing performance, and at the same time exhibits excellent corrosion resistance, high temperature resistance, and not easy to be deformed, which effectively prolongs the service life of the equipment.

- Flexible adaptation: the peanut butter filling machine supports both manual and automatic operation modes, and the filling nozzles can be replaced according to different materials, thus realizing the filling of a variety of products such as honey, fruit juice, edible oil, cream, peanut butter, ketchup and so on, which greatly enhances the versatility and adaptability of the equipment.

- Stable filling: Adopting stainless steel nozzles, its filling head also incorporates advanced anti-leakage technology to ensure the stability and safety of the filling process.

Filling machine common problems and solutions:

Unstable filling volume: there may be debris caught in the feed check valve, resulting in poor sealing and affecting the filling volume. The feed check valve should be checked and cleaned.

Leakage from the lower part of the cylinder: the piston seal is worn, and the seal needs to be replaced.

Pneumatic pipe leakage: check whether there is air leakage or rupture of the pneumatic pipe and air tube, repair or replace in time

Our well-built GT series peanut butter filling machine is designed to provide efficient, accurate and hygienic filling solutions for your peanut butter production line. With its excellent performance and reliable quality, it has become a professional choice trusted by many companies.